Permanent people : L. Pichon (Pr), J.B. Dubois (MCF), M. Drouet (IR)

Coll. DPMM-axe ENDO: P. Villechaise, J. Cormier

PhD students : Valentin Gazagne (2020 -2023) (PPNa – SIMAC), Renaud Génin (2021-2024) (P’ + LEM3-Metz)

We are interested in surface modifications by thermochemical treatments assisted by low pressure plasma and / or by ion implantation. We have a main (but not exclusive) objective of improving mechanical properties by creating layers of compounds (nitrides, oxides, etc.) or solid insertion solutions (nitrogen, oxygen, carbon, etc.). These studies are based on two original reactors: URANOS, a treatment reactor assisted by low pressure plasma and TAPIIR, a plasma based ion implantation reactor (PBII). The aim is to understand, in connection with the processing conditions, the mechanisms of chemical and microstructural modifications and to relate them to the induced properties of interest. Employed analytical techniques enable the chemical study of surfaces and the microstructural characterization at different scales. The properties of interest are then tested within P’ or as part of external national or international collaborations.

2015-2019 : Nickel based superalloys nitriding at moderate temperature

Nickel Based superalloys nitriding at moderate temperature (450°C) with plasma assistance was studied from 2011 to 2019, because of the efficiency of the corresponding treatments previously applied in P’ Institute to stainless steels and CoCrMo alloys which present similar structures and nitrides formers. Whatever the Ni-based superalloys (polycrystal or single crystal types, with or without γ’ and γ" structural precipitates) The formation of the metastable expanded γN phase (solid solution of N in the initial austenitic γ phase) was obtained like in the Fe- or Co-based alloys, although it appears less stable ; the γ’ and γ" precipitates, specifics to some Ni-based superalloys, were also shown to be more or less nitrided, depending on the studied superalloys. Concerning the induced properties, the hardness and the fatigue resistance were studied (Sébastien Chollet PhD thesis) ; their improvement was limited by two factors : (i) the damages in the surface treated layer due to the high stress level induced by the nitriding (ii) the application temperature of the treated superalloys has to remain low in order to avoid the decomposition of the γN phase to nitrides, degrading the oxidation/corrosion resistance. In order to clarify these points the Ni-based superalloys nitriding study was continued in 3 directions:

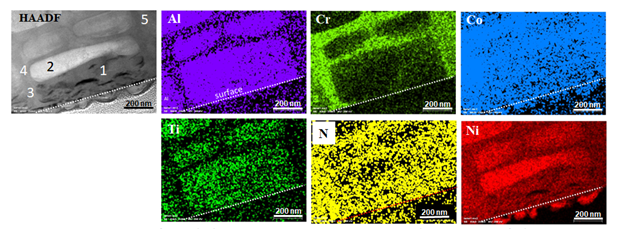

1)-TEM study (HRTEM, STEM, HAADF, EDS) at low scale of the nitride γ et γ’ phases: it was shown that (i) the nitride γ phase is finally relatively heterogeneous, the γN phase being more or less decomposed in CrN nanoprecipitates. (ii) The nitrided γ / γ’ interfaces remains partially coherent and high stress and plasticity damages (dislocations, shear strains) are observed in the γ phase.. (iii) the nitrided γ’ precipitates can incorporate as much nitrogen than the γ phase. They are then composed of nanometric nitrides (Al, Ti,…)N dispersed in an austenitic matrix.

2)-Understanding of the different behaviour of the γ’ precipitates face to the nitriding: nitriding of various Ni-based superalloys with different compositions and microstructures enables to demonstrate that the composition of the γ’ precipitates was responsible of the observed differences. This influence is not purely “chemical” but is relative to the variations of the mechanical properties of the with their composition. The most shear resistant γ’ precipitates (chemically close to Ni3Al) don’t incorporate any nitrogen because its diffusion within the γ’ is occurring thanks to the plastic damages induced by the compressive stress in the surrounding γN phase.

3)-Controling the maximum nitrogen content in order to limit the γN phase metastability (and decomposition in nitrides) and the induced damages: the nitriding conditions possible in the treatments rectors did not enable to obtain significant modifications of the nitrogen profiles nor microstructures ; the main controlling parameter remains the chemical composition of the alloy for a given treated depth. However ot was demonstrated that the nitrogen incorporation is proceeding through 3 successive steps : formation of a first ordered solid solution similar to Ni4N, then the expanded γN phase, and then the decomposition in CrN.

2018 -… : Plasma assisted treatments for multi-interstitials solid solutions in Titanium based alloys

Initiated by MixTi project (2017-2021 : Mixed interstitial phases; a novel approach to tailoring the surface properties of titanium) in collaboration with Department of Mechanical Engineering de DTU (Technical University of Denmark), this study is locally pursued by a PhD thesis with two financial support : INTERACTIFS Labex (P’) and DAMAS Labex (LEM3 – Metz). Instead of focusing on the very hard binary compounds (TiN, TiC…), the study is aiming to obtain a thick mechanically improved supporting layer by creating a multi-interstitials (N, O, C) solid solution. Various thermochemical treatments in P’ and DTU will be tried, trying to investigate the possible interactions in the different elements diffusion mechanisms, and combined with pre and post- SMAT treatments in LEM3 – Metz. The induced elasto-plastic properties and deformation mechanism will be investigated by SEM in situ mechanical tests (LEM3) and the mechanical properties will be determined by nano/micro indentation and finally fatigue tests (P’).

2019-… : HEA Nitriding

High Entropy Alloys (HEA) are under investigation for about 15 years and let see interesting properties and applications, by replacing some usual alloys. The nitriding of these HEA is poorly studied up to now whereas such thermochemical surface treatments can lead to unprecedent results and perspectives that our expertise in Fe, Ni, Co, Ti or Al-based alloys allows to understand.

A collaboration with ICMPE (Paris) laboratory was initiate because of their knowledge and capacity in producing such alloys (2 ANR projects HEA-NitroTop were deposited in 2020 and 2021 but unfortunately not approuved). Another way to obtain the based HEA materials was initiated in collaboration with the PPNa team by powder metallurgy (2 masters internships in 2019 and 2020). A PhD thesis started in 2020, firstly focusing on the different possible routes of AlxCoCrFeNi HEA synthesis by powder metallurgy (natural sintering, hot isostatic pressing, mechanical alloying…) and then on their nitriding. The choice of these HEA alloys is relative to the well documented literature on their synthesis and on the phases and elements similar to the previous usual alloys studied by the team. The first results are promizing as expanded nitride phase is also obtained by nitriding at moderate temperature.

International collaborations

- Plasma Based Ion implantation (PBII) of shape memory NiTi alloys and of Fe and Ti-based alloys in tube geometry (coll. INPE- Brésil)

- Surface treatments (plasma oxidation, implantation or deposition of Au, Pt or Pd) of Ti-based alloys for Hydrogen storage applications (coll. I-Themba et Rhodes University– South Africa)

- Luminescence properties modifications of Si and Al oxides by Ag, N, Ar, … ion implantation (coll. Rhodes University– South Africa)

Papers

Publications

M. Drouet, E. Le Bourhis, Low Temperature Nitriding of Metal Alloys for Surface Mechanical Performance

Materials, 16, 4704 (2023)

V. Parry, E. Le Bourhis, L. Pichon, M. Drouet, Relation between Mechanical Hardening and Nitrogen Profile of PBII Nitrided Titanium Alloy

Materials, 15, 9028 (2022)

M. Drouet, L. Pichon, Y. Vallet, E. Le Bourhis, T. L. Christiansen, Surface engineering of titanium alloy TiAl6V4 by multi-interstitial diffusion using plasma processing

European Journal of Materials 1 (2022)

Yichen Meng, M. Villa, K. V. Dahl, B. Wang, M. Drouet, J.-B. Dubois, M. A.J. Somers, T. L. Christiansen, Thermochemical surface hardening of Ti-6Al-4V: On the role of temperature and treatment media

Surface & Coatings Technology 422 127505 (2021)

M. Drouet, L. Pichon, J.B. Dubois, E. Le Bourhis, T. L. Christiansen, Surface engineering of titanium by multi-interstitial diffusion using plasma processing

Matec web of conferences, 321 11010 (2020)

M. Ueda, C. Silva, G.B de Souza, L. Pichon, High Temperature Plasma Immersion Ion Implantation Using Hollow Cathode Discharges in Small Diameter Metal Tubes,

J. Vac Sci and Technol. B, 37(4), 042902, (2019).

F. Noli, L. Pichon, O. Ozturk, "The influence of plasma-based nitriding and oxidizing treatments on the mechanical and corrosion properties of CoCrMo biomedical alloy"

Metallurgical and Materials Transactions A, 49(4), (2018) 1383-1396

M. Topic, L. Pichon, S. Nsengiyumva, G. Favaro, M. Dubuisson, S. Halindintwali, S. Mazwi, J. Sibanyoni, C. Mtshali, K. Corin, "The effect of surface oxidation on hydrogen absorption in Ti-6Al-4V alloy studied by elastic recoil detection (ERD), X-ray diffraction and nanohardness techniques "

J. Alloys and Compounds 740 (2018) 879-886

S. Nsengiyumvaira, M. Topic, L. Pichon, C. M. Comrie, C. Mtshali, "Oxygen depth profiling by resonant backscattering and glow discharge optical emission spectroscopy of Ti6-Al-4V alloy oxidized by ion implantation and plasma based treatment "

Nuclear Instruments and Methods in Physics Research B, 384 (2016) 50-60

S. Nsengiyumva, M.L. Chithambo and L. Pichon, "Influence of argon-implantation on conventional and phototransferred thermoluminescence of synthetic quartz"

Radiation Effects and Defects in Solids, 171 (2016) 328-339

D. Manova, C. Díaz, L. Pichon, G. Abrasonis, S. Mändl, "Comparability and Accuracy of Nitrogen Depth Profiling in Nitrided Austenitic Stainless Steel"

Nuclear Instruments and Methods in Physics Research B, 349 (2015), 106-113

F. Noli, P. Misaelides, A. Lagoyannis, L. Pichon, O. Ozturk, "Use of combination of accelerator-based ion-beam analysis techniques to the investigation of the corrosion behavior of CoCrMo alloy "

Nuclear Instruments and Methods in Physics Research B 331 (2014) 125-129

S. Chollet, L. Pichon, J. Cormier, J.B. Dubois, P. Villechaise, M. Drouet, A. Declemy, C. Templier, "Plasma assisted nitriding of Ni-based superalloys with various microstructures "

Surface and Coatings Technology, 235 (2013) 318-325

L. Pichon, J. Cormier, A. Declemy, S. Chollet, P. Villechaise, J.B. Dubois, C. Templier, "Plasma nitriding response at 400°C of the single crystalline Ni-based superalloy MC2 "

J. Mater Sci, 48 (2013) 1585-1592

A. Martinavičius, G. Abrasonis, A.C. Scheinost, R. Danoix, F. Danoix, J.C. Stinville, G. Talut, C. Templier, O. Liedke, S. Gemming, W. Moller, "Nitrogen interstitial diffusion induced decomposition in AISI 304L austenitic stainless steel”

Acta Materialia 60 (2012) 4065-4076

C. Tromas, J.C. Stinville, C. Templier, P. Villechaise, "Hardness and elastic modulus gradients in plasma-nitrided 316L polycrystalline stainless steel investigated by nanoindentation tomography”

Acta Materialia 60 (2012) 1965–1973

M. M. Silva, L. Pichon, M. Drouet, J. Otubo, "Roughness studies of NiTi shape memory alloy treated by Nitrogen Plasma Base Ion Implantation at high temperatures”

Surf. Coat. Technol. 205 (2011) S111-S114

J.C. Stinville, C. Templier, P. Villechaise, L. Pichon,"Swelling of 316L austenitic stainless steel induced by plasma nitriding"

J. Materials Science 46 (2011) 5503–5511

L. Pichon, S. Okur, O. Ozturk, J.P. Rivière, M. Drouet,"CoCrMo alloy treated by floating potential plasma assisted nitriding and plasma based ion implantation : influence of the hydrogen content and of the ion energy on the nitrogen incorporation"

Surf. Coat. Technol. 204 (2010) 2913-2918